- Teknolabo A.S.S.I. S.r.l.

Main menu:

- Home

- About us

- Products

- Distribution

- Support

- Contacts

- Certificates

Industrial lines for culture media pouring on Petri and Rodac/Contact plates, Swabs and Slides for urino-

Different solutions for the filling of 800 dishes per hour (single channel line), up to 10.000 dishes per hour

Laboratory solutions for filling from 450 up to 800 dishes per hour

Complete solutions for the process

TKA produces a complete line of ROS systems for the production of ultra-

Media preparators for industrial plants

TKA Teknolabo A.S.S.I. produces a special culture media preparators line with capacity up to 500 liters. These preparators can feed the bigger industrial lines.

TKA Teknolabo A.S.S.I. S.r.l. manufactures industrial lines for filling Petri dishes, Contact plates, Swabs and slides since 1982. These lines can work on 1,2,3,4,6,8,10,12 channels in order to satisfy the need of our customers.

The manually pouring of Petri dishes and slides for microbiological purpose is expensive as for the time required to obtain satisfactory products as for casual pollution that may intervene during the process.

The TKA systems have been developed in order to eliminate the above mentioned problems allowig a real microbiologic analysis standardization at a reasonable cost. The wide range of TKA industrial lines plate pouring units can process from 1000 up to 12.000 dishes per hour, with one or more sectors, or Contact plates, according to the real needs of the user.

TKA Teknolabo A.S.S.I. lines can work with dishes with different diameter starting from 50 up to 150 mm.

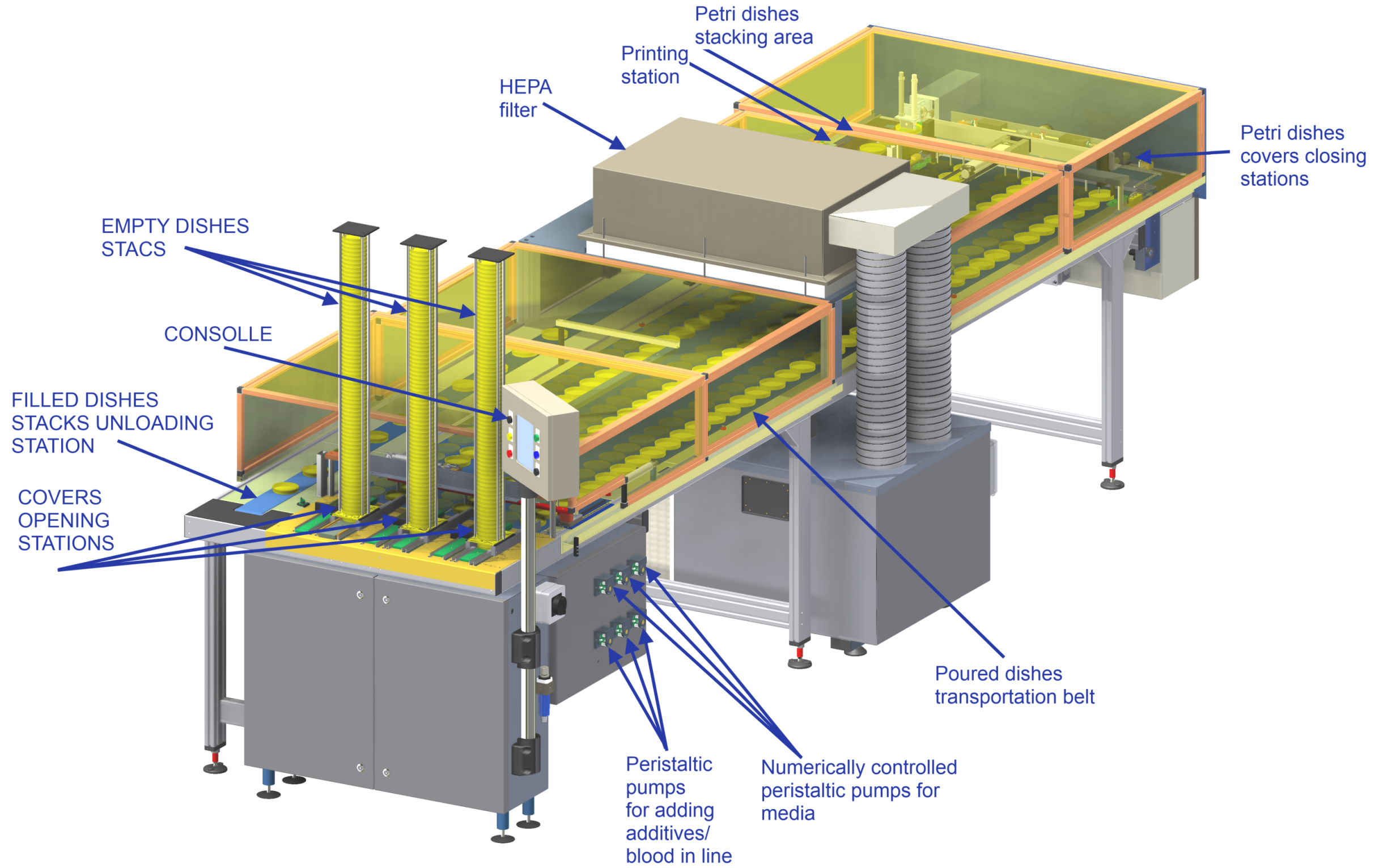

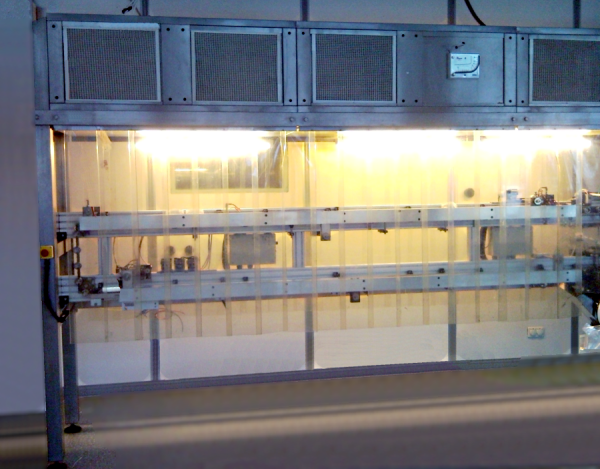

The external frame, the surface and the delivery tunnels are stainless steel AISI304 made, like the laboratory filling systems. The unstacking of the empty dishes and the opening operations are completely automated. If it is required, for production scheduling and needs, it is possible to easily set up the line for the processing of different dishes type. This operation is simple and fast and does not require any mechanical adjustment. To keep sterility conditions each line is equipped with UV lamps on the dispensing tunnel. These lamps can be switched on when the line is in stand-

TKA designs and manufactures culture media preparers able to fill the faster industrial plants. Each industrial line can be equipped with a culture media preparer with the proper capacity, up to 600 Liters. TKA can manufacture standard industrial lines or custom ones developed on the customer's specifications and request.

All the lines can be set up for the Rodac plates processing as optional request or for two or three sectors dishes pouring. TKA produce lines for the media dispensing on urinoculture slides, or swabs. Like theindustrial lines these plants can be realized on custom specifications.

Industrial line for the filling of Petri dishes

Watch the video Sign-

Industrial line for the filling of Petri and Rodac dishes

Watch the video Sign-

TKA industrial lines can be designed for working on different types of plates, with different diameters, Rodac, or two and three sector plates, on the same line without particular mechanical regulations.

Furthermore the flexibility of our lines permits to execute filling operations on different format plates and with the same line also on Rodac plates.

The four and six channel lines permit the use of two different types of culture media.

Different available models are coded as follows:

795C01X "Compact" filling line with speed up to 1000 plates/hour

795B01X Single channel filling line with speed up to 1000 plates/hour

795B02X channels filling line with speed up to 2000 plates/hour

795B03X Three channels filling line with speed up to 3000 plates/hour

795B04X Four channels filling line with speed up to 4000 plates/hour

795B06X Six channels filling line with speed up to 6000 plates/hour

795B08X Six channels filling line with speed up to 6000 plates/hour

795B10X Six channels filling line with speed up to 6000 plates/hour

795B12X Six channels filling line with speed up to 6000 plates/hour

The letter X indicates the available options on each line:

A Kit for filling two sectors plates containing a plate polarizer and a double body peristaltic pump

B Format change option to work with plates of different sizes (from 50 to 150mm)

C Option to install a chilling unit for the plates. This option permits a faster cooling of the plates

R Kit to operate with Contact or Rodac type plates

I Subsidiary unit for the automatic online inspection of the quality of the poured plates and the rejection of the ones found not suitable to be packaged (e.g. incomplete pouring, presence of bubbles or particles, broken plate, etc.) -

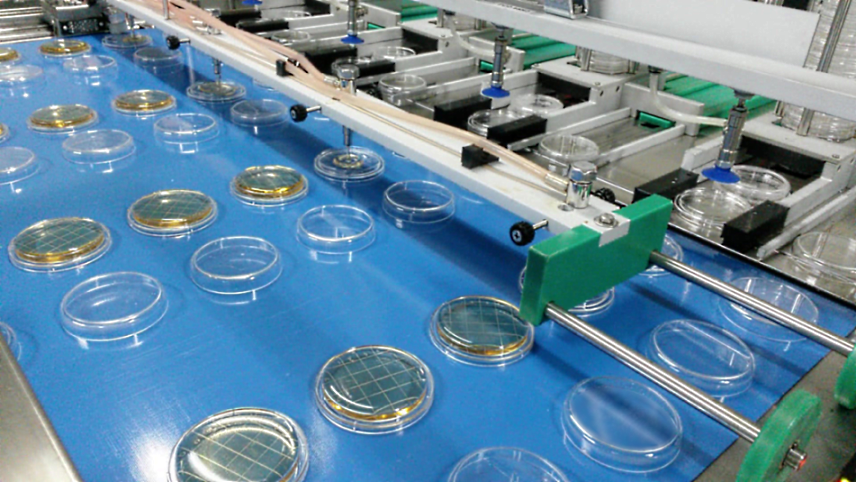

Industrial lines for filling dishes with diameters from 50 to 150mm or Contact or Rodac. The number of channels on which the line can work goes from one up to six on the basis of the required speed. Each line is complete of the dispensing equipment and of a plate opening and closing automatic system. The empty dishes stacking inlet area can contain up to 60 plates per channel (referred to standard height plates). The media dispensing system uses a numerically controlled multiple sections peristaltic pump, furthermore, the line is provided with a multiple section peristaltic pump for adding additives/blood on line. The output plates are stacked in a numerically programmable way. The four and six channels lines can have two stacking areas as option, hence on these models it possible to use two different kinds of Agar. The plates are dried thanks to a sterile air flow filtered through a Hepa filter. When the machine is not working some UV lamps maintain the sterile conditions of the line.

In order to satisfy the needs for a "compact" systems, where not enought space is available in the pouring room, we have developed an automatic compact line to fill from 50 to 150 mm Petri dishes and/or Contact plates. The line has been designed to use a single transportation belt, where the empty plates, once opened, are automatically disposed to form a matrix with different dimensions depending on the diameter of the plates to be poured. The line uses a single dispensing noozle able to sequentially pour the plates’tale, immediately after their opening, by moving along the plates tale on the inlet of the transportation belt. The line is manufactured following the standards used for the industrial lines. The drying is performed by means of convoyed sterile air flow, chiled as option (the motor-

Three channels industrial line layout for Petri and Contact dishes filling

Petri dishes opening and dispensing system

Industrial line for Slides preparation